How We Saved a Restaurant Chain 44 Hours Per Week with WhatsApp Order Automation

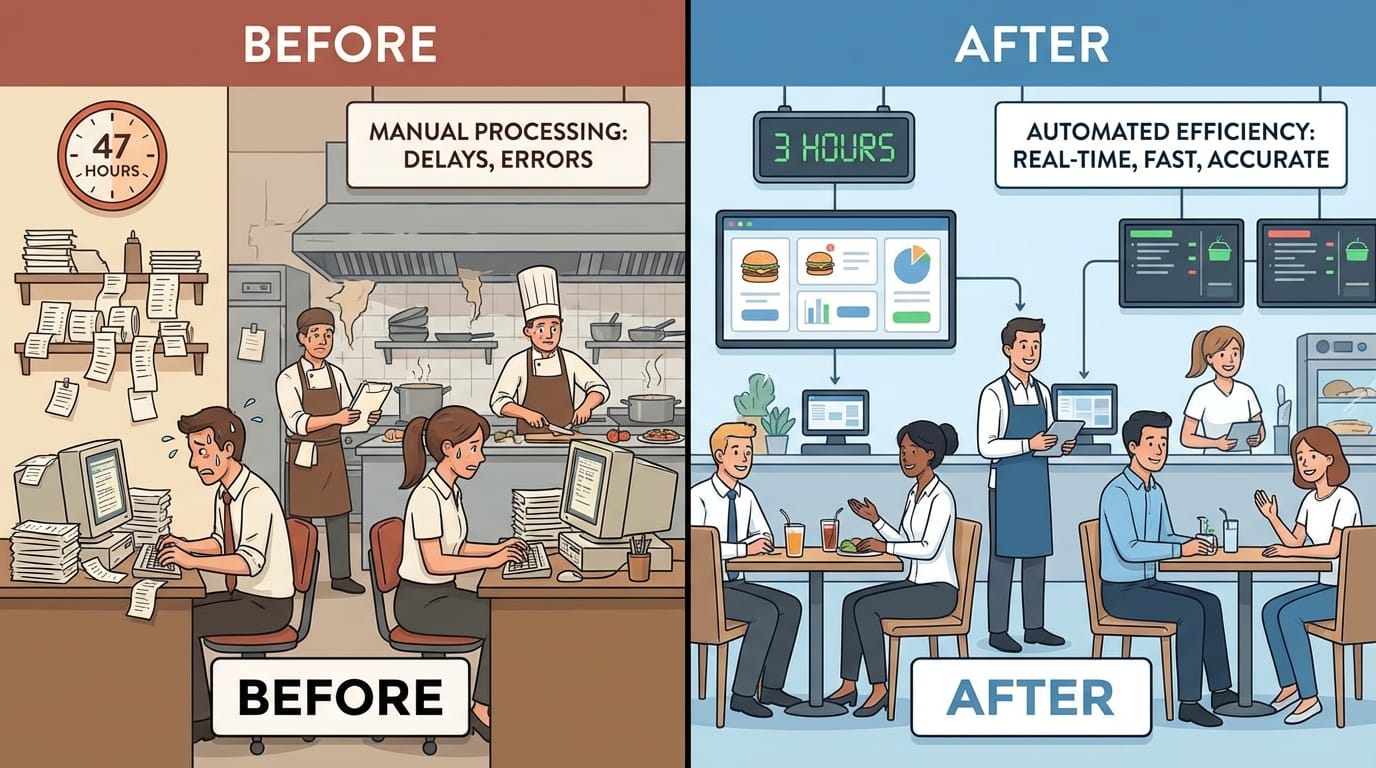

A regional restaurant chain with four locations was manually entering every WhatsApp order into their POS system. 47 hours per week across all locations. That's more than a full-time employee just copying messages into a computer.

The owner put it simply: "We're paying people to be human copy-paste machines. There has to be a better way."

There was. We built an automation that cut that 47 hours down to 3. Here's exactly how it works and what it cost.

The Problem: Manual Order Entry at Scale

The chain had embraced WhatsApp for takeout orders because that's where their customers were. Smart move for customer experience. Nightmare for operations.

Each location had a staff member monitoring WhatsApp during service hours. They'd receive an order, manually type it into the POS system, confirm with the customer, then notify the kitchen. Every. Single. Order.

Breakdown of time per order:

- Reading and interpreting message: 30 seconds

- Entering into POS: 2 minutes

- Confirming with customer: 1 minute

- Notifying kitchen: 30 seconds

- Total: 4 minutes per order

With 700+ orders per week across all locations, that's 47 hours of manual work. At €15/hour labor cost, that's €705 weekly or €36,660 annually.

But the real cost was higher. Order errors happened. Customers got frustrated with slow confirmation times. Kitchen staff missed orders during rush periods. The manual process was a bottleneck.

The Solution: WhatsApp Business API + Workflow Automation

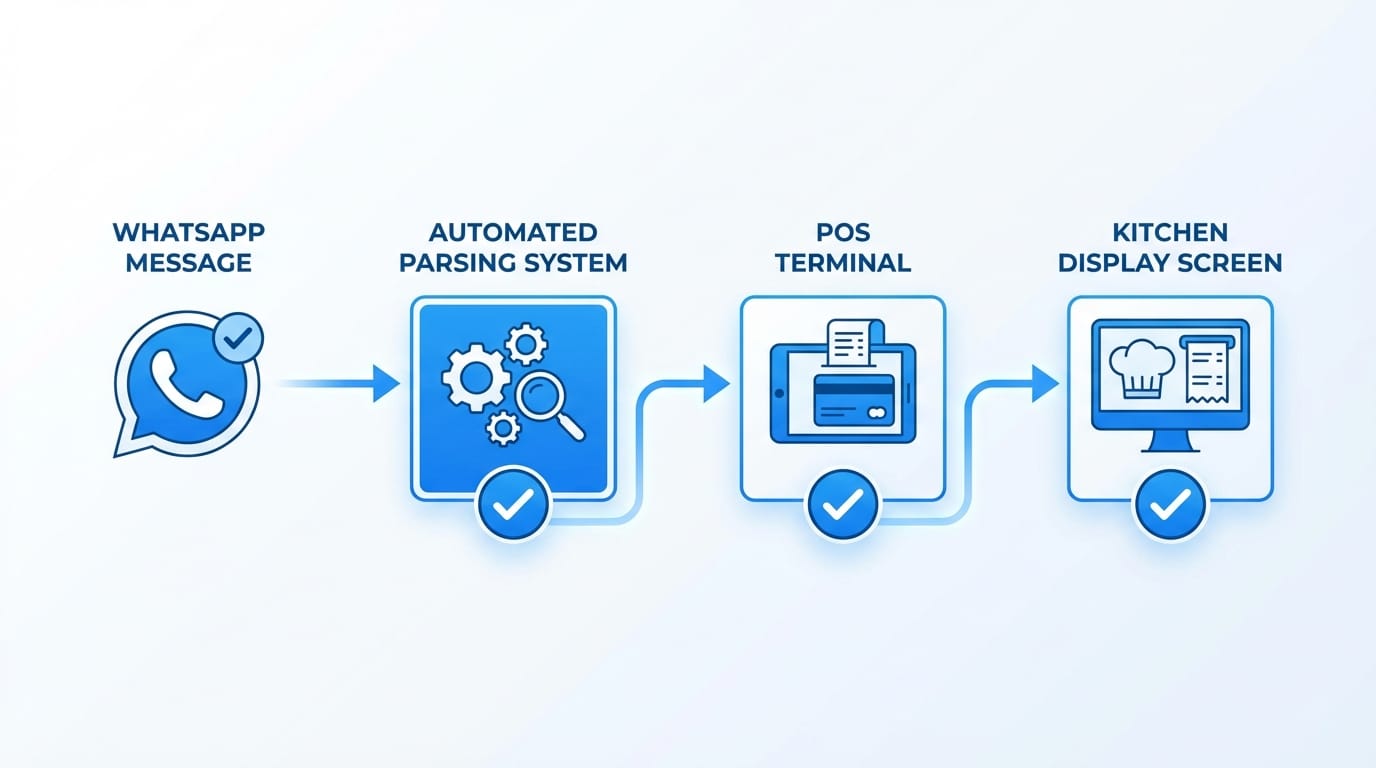

We built a restaurant automation workflow connecting WhatsApp directly to their existing POS system. No app switching. No manual typing. Orders flow automatically from customer message to kitchen display.

The technical stack:

WhatsApp Business API — Official business messaging platform. Receives orders, sends confirmations, handles customer communication.

n8n workflow automation — Open-source tool that connects systems. Parses order messages, validates format, routes to correct location.

POS system integration — Direct API connection to their existing point-of-sale. Creates orders automatically with correct items, prices, modifiers.

Kitchen display system — Real-time notification to kitchen staff. Orders appear immediately with preparation instructions.

The workflow handles everything:

- Customer sends order via WhatsApp

- System receives message, identifies location

- AI parses order text into structured data

- Validation checks: items exist, modifiers valid, location open

- Order creates automatically in POS

- Kitchen display updates in real-time

- Customer receives confirmation with estimated time

- Staff monitors dashboard, handles exceptions only

Results: 44 Hours Saved Weekly

Time reduction:

- Before: 47 hours/week manual processing

- After: 3 hours/week monitoring exceptions

- Saved: 44 hours/week

Financial impact:

- Labor cost savings: €660/week (€34,320/year)

- Initial development: €8,500

- Monthly maintenance: €150

- ROI achieved in: 13 weeks

The 3 remaining hours? That's just staff checking a dashboard for any orders the system flagged as unclear. Happens about 5% of the time when customers use very unusual wording. Everything else is fully automated.

Secondary Benefits: Beyond Time Savings

The owner noticed improvements beyond the spreadsheet:

Order accuracy increased. Human transcription errors disappeared. The system reads exactly what the customer wrote. Fewer remakes, fewer complaints.

Service speed improved. Confirmation messages went from 3-5 minutes to under 30 seconds. Kitchen received orders instantly instead of waiting for staff to manually notify them.

Peak hour stress decreased. During lunch and dinner rush, the bottleneck used to be order entry. Now orders flow continuously without staff scrambling to keep up.

Customer satisfaction improved. Faster confirmations, fewer errors, consistent experience across all locations. Google reviews mentioning order accuracy went up noticeably.

One staff member said: "I actually get to focus on customer service now instead of typing all day. It's completely different work."

Technical Implementation: What Actually Happened

At Etere Studio, we've found that restaurant automation projects succeed when you work with existing systems rather than replacing them.

Phase 1 was understanding their current POS. We spent a week documenting their menu structure, modifier logic, pricing rules. Every restaurant has quirks in how they handle substitutions, special requests, combo meals. The automation needs to respect that.

Phase 2 was building the WhatsApp Business API connection. We set up webhook endpoints, tested message formats, built the parsing logic. The AI component learned to interpret common order variations: "extra cheese" vs "add cheese" vs "cheese on side".

Phase 3 was POS integration. We used their API to create orders programmatically. Testing was crucial here. We ran hundreds of test orders to ensure pricing, tax calculation, inventory updates all matched manual entry perfectly.

Phase 4 was kitchen display integration. Some locations had modern screens, one still used printed tickets. We made both work with the same automation.

Total implementation time: 6 weeks from contract to full deployment across all locations.

What Makes This Work for Restaurants

This approach works well when:

High order volume via messaging. If you're getting 100+ WhatsApp/SMS orders weekly, automation pays for itself quickly.

Standardized menu. The more consistent your menu structure, the easier automation becomes. Frequent menu changes require more maintenance.

Digital POS system. You need a POS with an API or integration capability. Legacy systems without APIs are much harder.

Staff buy-in. The team needs to trust the automation and know when to intervene. Training matters.

It's less suitable when:

Highly custom orders. If every order requires extensive back-and-forth clarification, automation becomes complex.

Irregular hours or processes. The system needs consistent rules to follow.

Very small volume. Under 50 orders weekly, the time savings don't justify development cost.

Real Owner Perspective

The owner (we'll call him Marco) was skeptical at first:

"I thought automation meant replacing people or having some robotic experience. But it's the opposite. My staff are happier because they're not doing repetitive computer work. Customers are happier because service is faster and more accurate. And honestly, I'm happier because I'm not paying someone €15/hour just to copy-paste."

He also mentioned something we hear often: "The ROI was obvious from the numbers, but what surprised me was how much smoother operations feel. Less chaos during busy periods. That's hard to quantify but very real."

Practical Next Steps for Restaurant Owners

If you're considering something similar:

- Track your current time. Measure how many hours per week you spend on manual order processing. Be honest about the real number.

- List your friction points. Where do errors happen? Where do orders get delayed? Those are automation opportunities.

- Check your POS capabilities. Does it have an API? Can it integrate with external systems? This determines feasibility.

- Calculate your ROI. Hours saved × hourly labor cost × 52 weeks. Compare that to development cost plus annual maintenance.

- Start with one location. Test the automation at a single site before rolling out to your entire chain.

We're seeing more restaurant automation workflows like this. Not because technology is trendy, but because the business case is clear. When you're spending thousands of hours annually on repetitive data entry, automation stops being a nice-to-have and becomes obvious.

Building restaurant automation that actually works? We've done this for hospitality businesses across Europe. If you're spending serious time on manual order processing, let's talk about what's possible for your operation. Get in touch